_______

Inconsistent temperatures can lead to spoilage, risking recalls and fines. An automated monitoring system that continuously tracks temperatures in coolers, freezers, and hot cases, catching temperature & humidity fluctuations before they become a problem, is therefore something that Retail Companies like Tropic look for.

Done in partnership with:

Dealing with inefficiency

In grocery retail, food safety does not fail because people do not care: it fails because manual temperature checks do not scale. When monitoring depends on periodic walkthroughs and handwritten logs, you get gaps: missed readings during peak hours, inconsistent documentation between stores, and delayed discovery of excursions.

Across the industry, automated monitoring is adopted for precisely these reasons: continuous tracking, real-time alerts, and audit-ready reporting reduce risk, reduce waste, and free teams from repetitive tasks.

Tropic Retail is a leading Bosnian high level retail chain headquartered in Banja Luka, Bosnia and Herzegovina. Founded in 1986, it has grown to become one of the most successful domestic retailers in the country, primarily specializing in food, beverages, and personal care products. The company operates approximately 80 supermarkets nationwide.

Tropic launched this pilot with a clear objective: make food compliance monitoring dependable in real store conditions: busy shifts, many cold points, and limited time for manual routines. The scope covers the places where drift happens and where it matters most: food fridges (positive temperature), freezers (negative temperature), front deli areas, and cold vitrines, with temperature and humidity tracked as required.

Tropic Retail is a leading Bosnian high level retail chain headquartered in Banja Luka, Bosnia and Herzegovina. Founded in 1986, it has grown to become one of the most successful domestic retailers in the country, primarily specializing in food, beverages, and personal care products. The company operates approximately 80 supermarkets nationwide.

Tropic in Banja Luka is the largest supermarket in the chain.

Challenges

- Risk of compromised food, lawsuits

- Costly reactive maintenance, downtime

- High costs of manual compliance checking

- Issues discovered late

- Difficult to standardize across stores

Solution

The pilot uses a simple principle: measure continuously, alert only when needed, and keep the record clean for compliance. Wireless sensors capture readings in refrigerators, freezers, deli counters and vitrines, while managers and quality teams can review trends, download reports, and act on excursions without waiting for the next manual round.

This approach aligns with widely used food safety practices that emphasize monitoring at critical control points, using automated alerts and tamper-resistant records to make audits and corrective actions easier.

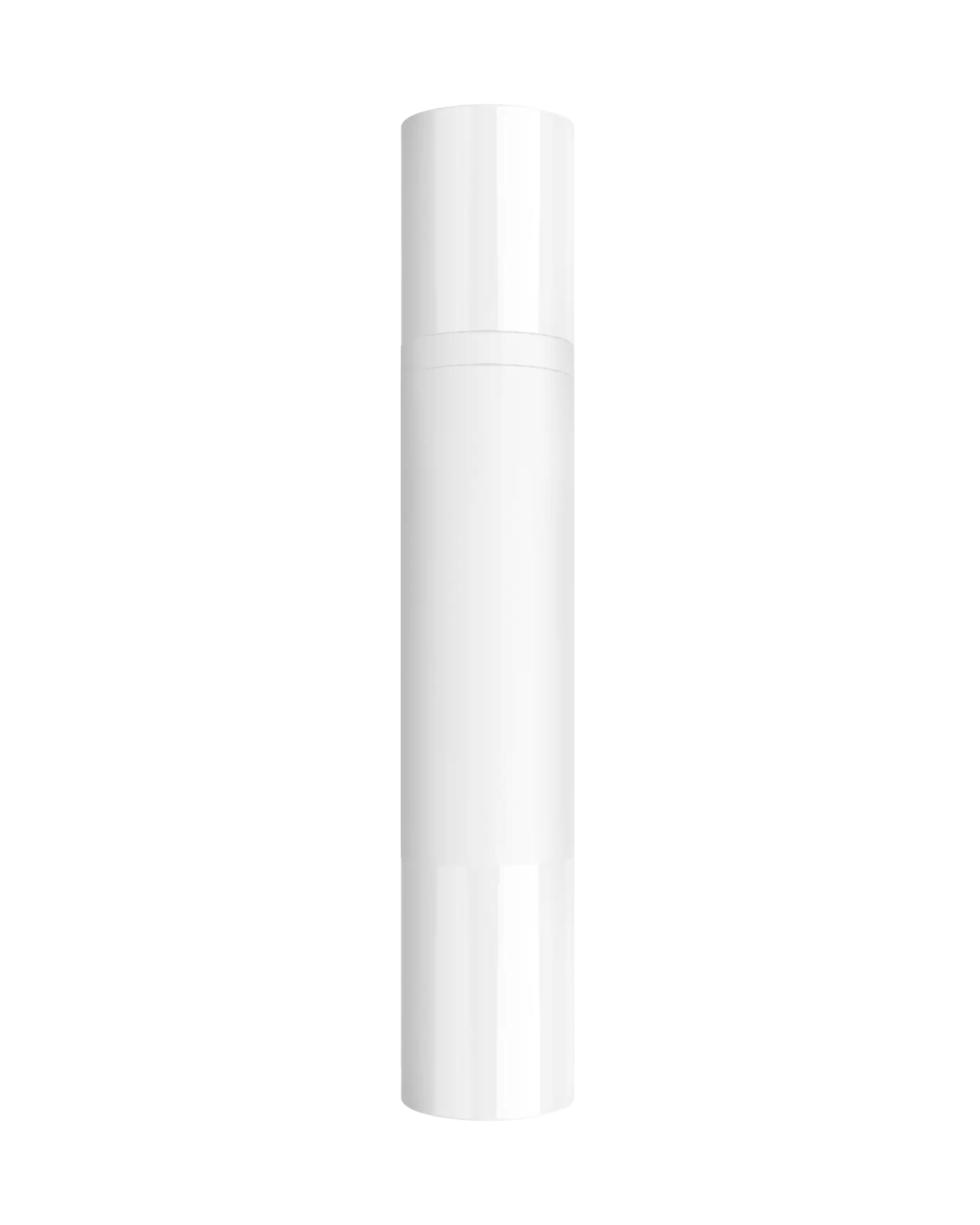

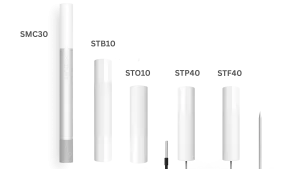

Senzemo has a range of sensors dedicated for food safety monitoring.

Monitored areas:

- Refrigerators & chilled cabinets (food fridges, back-of-store and sales-floor)

- Freezers / negative temperature zones

- Front deli area (conditions affecting quality and presentation)

- Cold vitrines (critical display storage)

Measure parameters:

- Temperature

- Humidity

Sensors deployed:

- STP40 — Temperature probe for freezers

- STO10 — Temperature only

- SMC30 — Temperature & humidity

Temperature and Humidity measurements with SMC30 at the meat deli.

Senstick Temperature Probe STP40 underneath the salad bar.

Senstick Microclimate SMC30 inside frozen items display section.

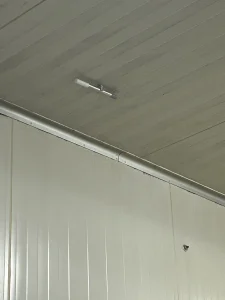

In the front-of-store, the deployment is deliberately dense: well over 50 sensors are distributed across the deli zone, open and closed fridges, small vitrines, display cases, and category-specific points (meat, pastry, frozen items, etc.). The idea is to measure at the places that actually drift (where doors open frequently, where airflow is uneven, and where display cases are exposed to customer traffic) so the data reflects reality, not best-case assumptions. Temperature and humidity measurements are transmitted via LoRaWAN, and the implementation is intentionally lean: only three gateways cover the entire deployment, with no signal stability issues reported.

Cold rooms use STP40 (probe inside, node outside). Plus fridges use SMC30 (temp + humidity).

In the back-of-store, where cold rooms and warehouse storage introduce different constraints, the installation is adapted to how equipment is used and serviced. For freezing / minus-temperature fridges, Tropic uses STP40 probe sensors so the probe sits inside the cold environment while the node remains outside, protecting radio performance and simplifying access without compromising measurement integrity. For plus-temperature fridges, they use SMC30 sensors where temperature and humidity context helps explain quality issues and operational anomalies. Where the requirement is strictly temperature logging (and humidity does not add value), STO10 temperature-only sensors provide broad coverage efficiently.

All the data is available in real-time on the KUEM Nexavia platform, hosted by Telegroup.

Benefits

- 25 min/day saved per store by removing manual temperature checking

- Reduced food inventory loss

- Lower risk of food contamination

Why LoRaWAN is the perfect fit for Tropic’s rollout

For a multi-site retailer, temperature and humidity monitoring only works if it remains reliable when scaled—across many fridges, vitrines, and storage zones, with minimal infrastructure and minimal maintenance. LoRaWAN fits that reality particularly well.

- It scales to high sensor density without complexity.

Tropic’s pilot already uses 50+ sensors across front-of-store areas (deli, displays, vitrines, fridges) while relying on only three gateways for the whole deployment—without signal issues. This kind of “many endpoints, few gateways” scaling is exactly what LoRaWAN is designed for. - It penetrates challenging environments.

Retail cold points are often problematic for radio: metal cabinets, dense shelving, back rooms, and mixed construction. LoRaWAN’s long-range, robust modulation is well-suited to maintain connectivity through those obstacles, avoiding the “dead zones” that often appear with short-range technologies. - It keeps operational effort low.

Unlike solutions that require store Wi-Fi credentials, frequent reconfiguration, or many repeaters, LoRaWAN deployments can be kept simple and standardized. Once gateways are placed and coverage is confirmed, adding new sensors is straightforward—ideal for a rollout from pilot to 77 stores. - It enables long battery life.

Compliance monitoring needs continuous operation without constant battery replacement. LoRaWAN’s low-power communication is optimized for sensor devices that send small packets at regular intervals, supporting multi-year battery operation in typical monitoring patterns. - It supports clean, centralized management.

LoRaWAN is built for centralized fleet monitoring—consistent device onboarding, unified data flow, and easier governance across many locations. That matters when compliance reporting must be standardized across dozens of stores rather than managed ad hoc.

LoRa is perfect for retail food monitoring cases, as it is easily scaled (across many fridges, vitrines, and storage zones, with minimal infrastructure and minimal maintenance).

There are only 3 gateways accross whole Tropic Banja Luka LoRaWAN deployment!

Long life, reliable monitoring, easy deployments are what makes LoRaWAN sensors perfect for these types of usecases.

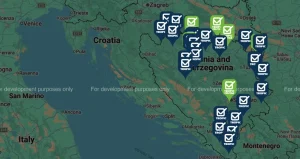

Built to scale to 77 units

The pilot is not only validating technology: it is validating a repeatable store playbook: where sensors go, what thresholds trigger action, who receives alerts, and what reports are used internally. That is what makes the next step straightforward: consistent rollout across all 77 units, with the same compliance standard everywhere and less operational variation between stores.

Tropic is planning to rollout this food compliance solution to other units in the next few years.

↓

For specific food type monitoring, where food core temperature is important see our Blog post Food Simulant Wireless Monitoring for more.